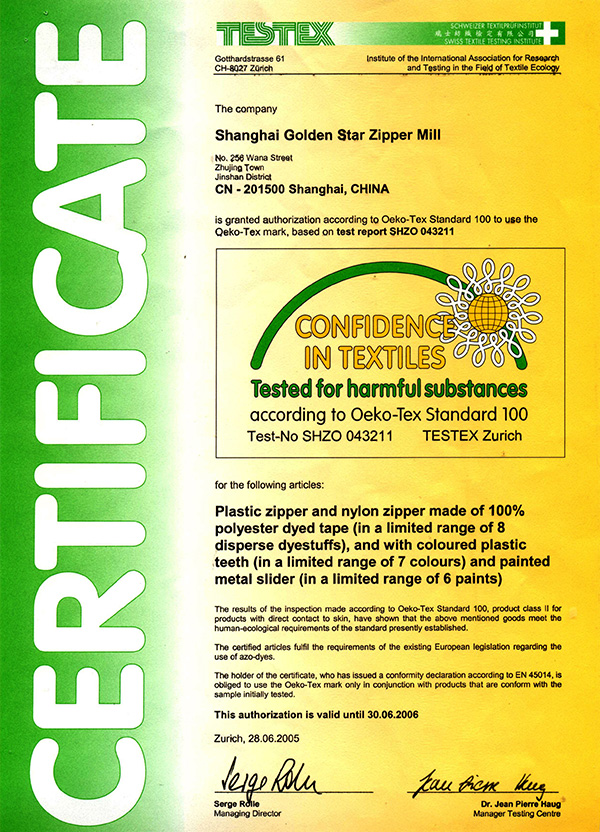

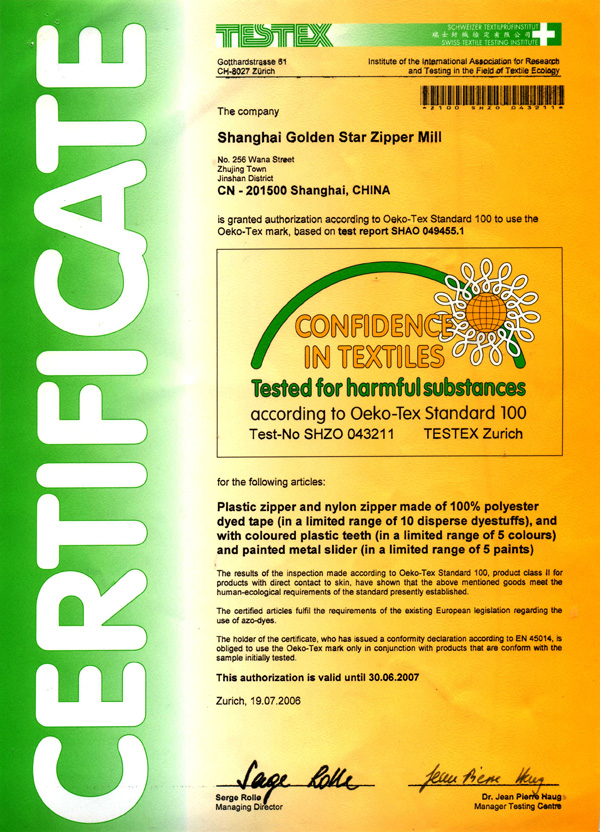

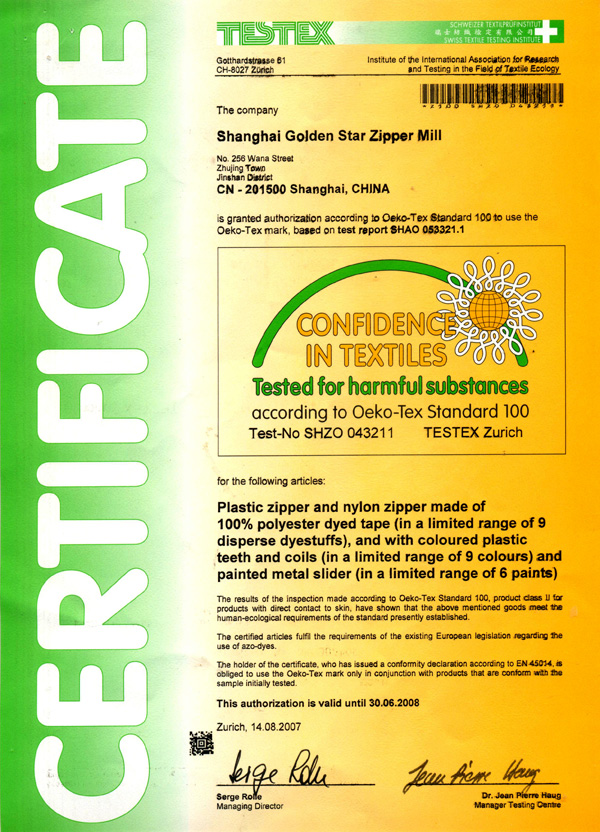

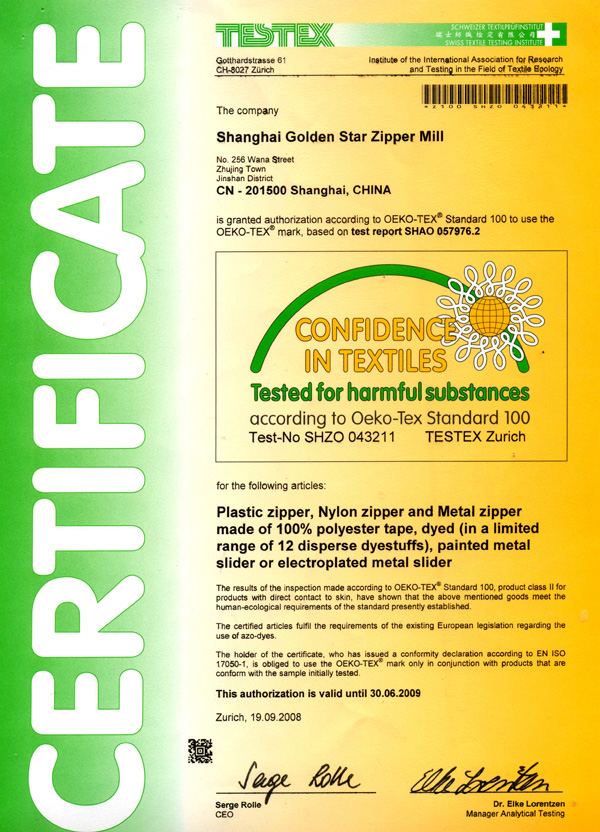

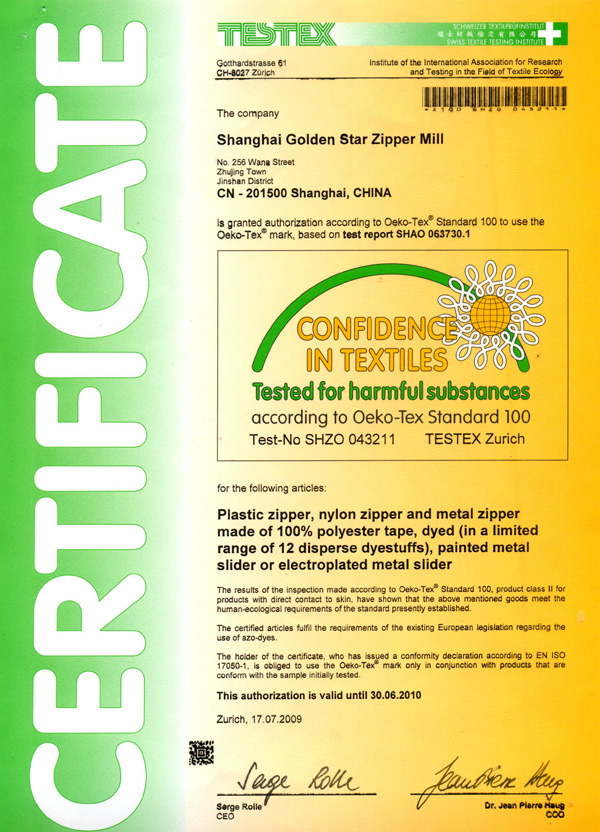

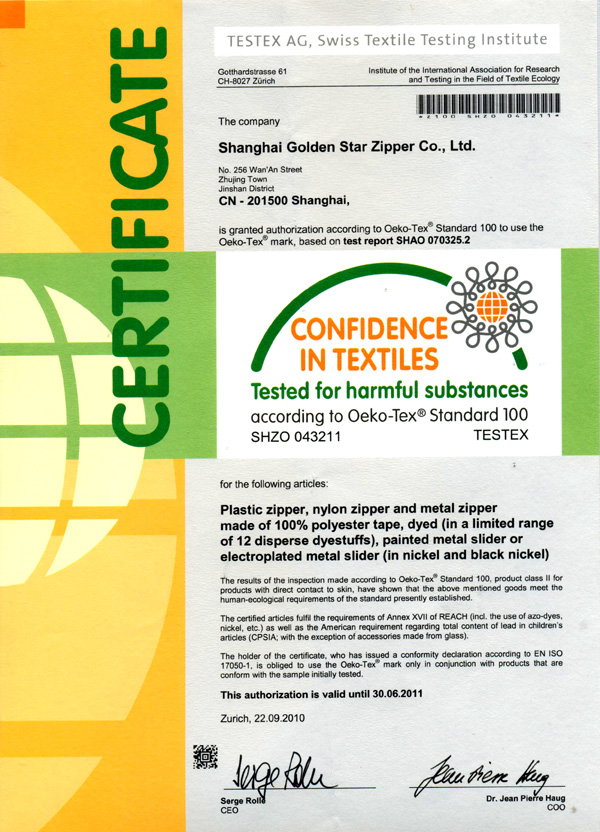

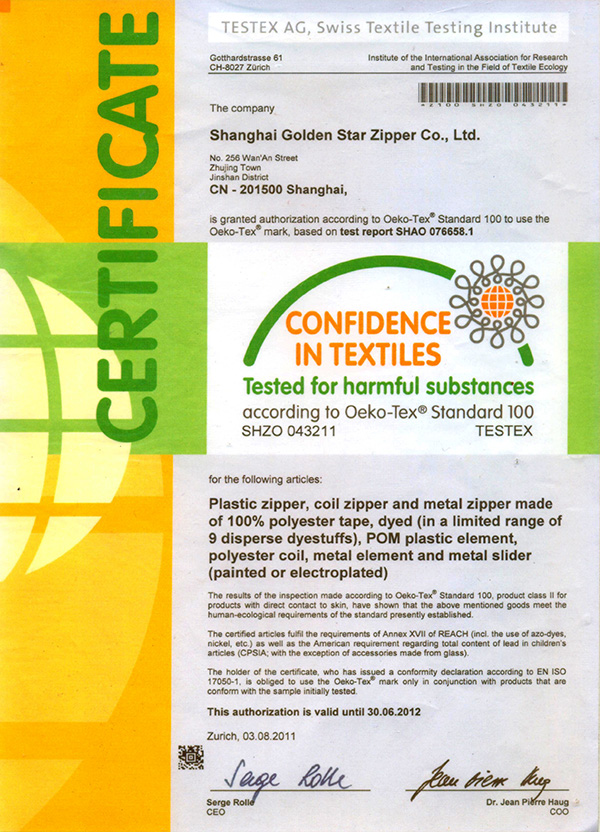

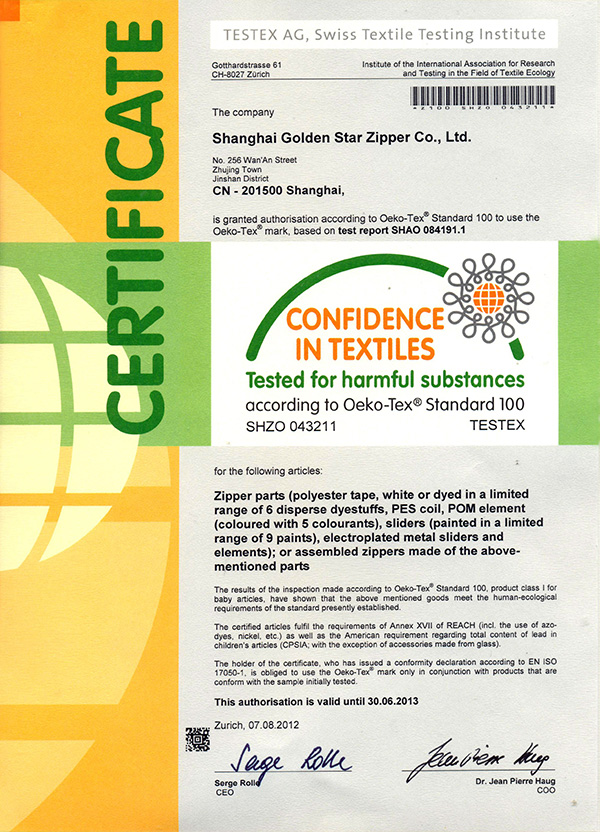

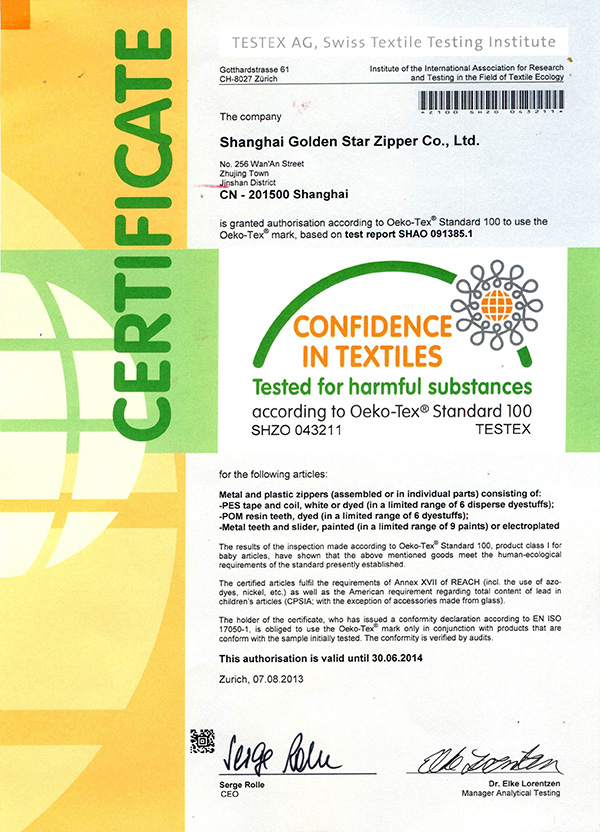

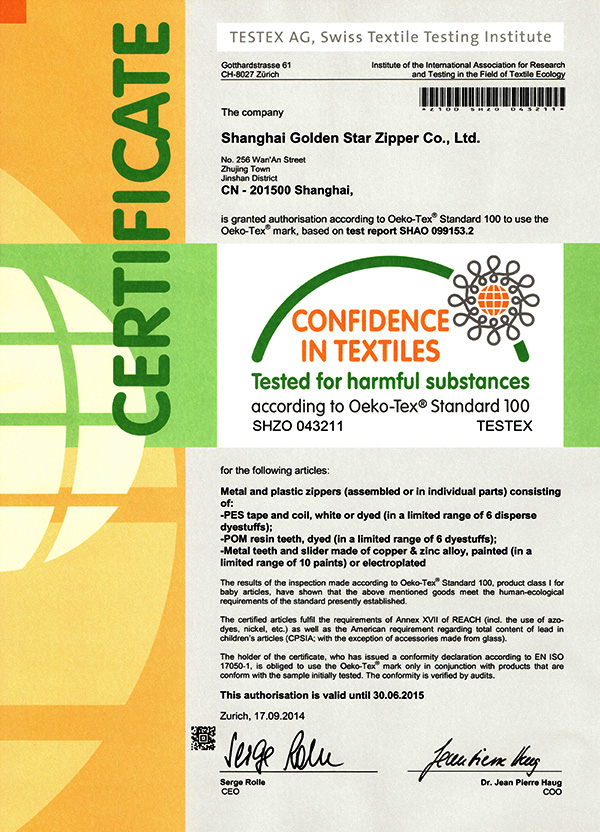

Shanghai Golden Star Zipper Co., Ltd (SGS) was called Shanghai Golden Star Zipper Mill, established since 1984, is one of the earliest zipper manufacturers who import equipment and production skills in China. SGS owns complete production equipment and process. SGS keeps a sharp eye on R&D and always try to improve her own products base on requirements of market all the way over 30 years. SGS has her own weaving, dying department for zipper tapes; die casting molding, designing and surface treatment department for sliders and various finishing process machine to meet all kinds of customer requirement, SGS design for customer, care for customer, rush for customer, always try her best to meet customer requirement and delivery. SGS believes sourcing control, all raw material is strictly controlled and properly recorded for tracing back especially chemical products in all dyeing and cleaning process. SGS was certified with Oeko-Tex Standard 100 Class II since year 2005. In year 2012, SGS upgraded Oeko-Tex Standard 100 cert into Class I at the same time SGS product is also certificated with Intertek SVHC chemical requirement. Since year 2009, SGS ERP system is online, compare to other company, SGS ERP system was founded and designed according to her own requirement, 100% ensure all process is controlled and traceable.

SGS’s customer is now covering America, Europe, South East Asia, Korea and Japan. SGS is also established business with various Branded customer, recognized and accept with them.

Life long improving is the belief of SGS. SGS is also keeping a sharp eye on energy conservation and emission reduction to make our world a better world. Hope SGS could serve you as your best partner.

1984

Project preparing of Shanghai Golden Star zipperMill.

1985

Shanghai Golden Star zipper Mill Established

Full import equipment of Nylon zipper set up to production.

1989

First Brand “JS” registed and promoted to the market.

1992

Shanghai Zhongxin Cloth Accessory Co., Ltd was established by Shanghai Light Inc. ; Hongkong Keehing and Shanghai Golden Star zipper Mill.

Delrin (Vislon) Zipper production equipment imported and set up into production.

1996

Metal zipper Production equipment imported and set up into production.

1997

Mr. Qinlian Xia was nominated as Factory Director of Shanghai Golden Star Zipper Mill.

2000

SGS was certifed with ISO 9000

2001

SGS was certified with ISO 9001:2000

Shanghai Opec Conference nominated SGS zipper for meeting bag.

2003

SGS is qualified to have self-support (direct) export right, SGS zipper is promoted to oversea market.

2004

Production Equipment upgraded to be full-automatic.

2005

SGS was certified with Oeko-Tex Standard 100 Class II.

Shanghai Yutian zipper Manufacturing Co., Ltd was established, pre-process (tape preparing process) capacity was expanded.

2009

SGS started ERP project with interal team.

Nylon Water Proof zipper R&D project started.

2010

Test running of ERP system.

”SGS” brand was registed, “SGS” branded zipper was promoted to oversea market.

Company name changed into Shanghai Golden Star Zipper Co., Ltd. Mr. Qinlian Xia was nominated as President.

2011

Company re-arranged and sub-factory was set up to expand capacity.

Self developed Water Proof zipper equipment was set up into production.

2012

ERP system upgraded, production process was merged into system, process was controlled by system.

SGS was certified with Oeko-tex Standard 100 Class I.

2013

ERP system upgraded, bar code system was merged into system, tracing system was set up.

Finishing equipment upgraded, daily capacity raised into 0.8 million pcs per day.

2014

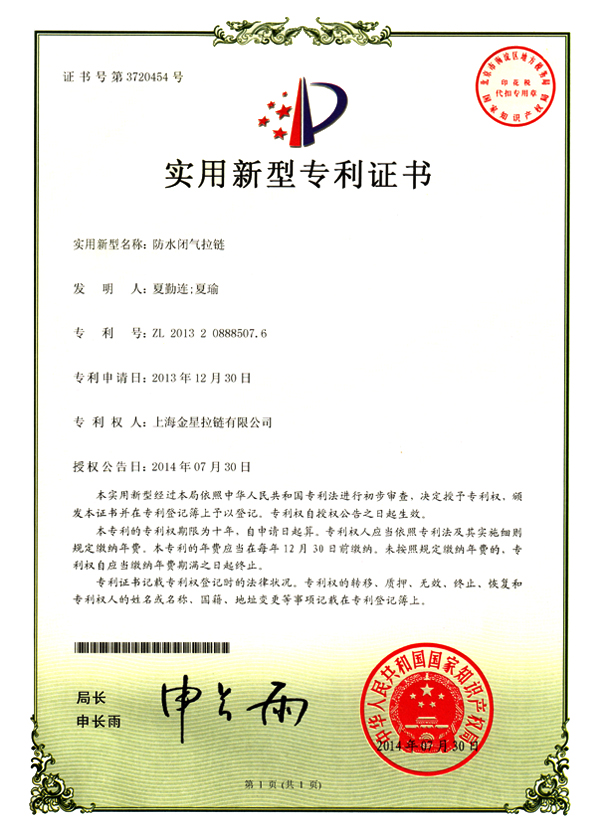

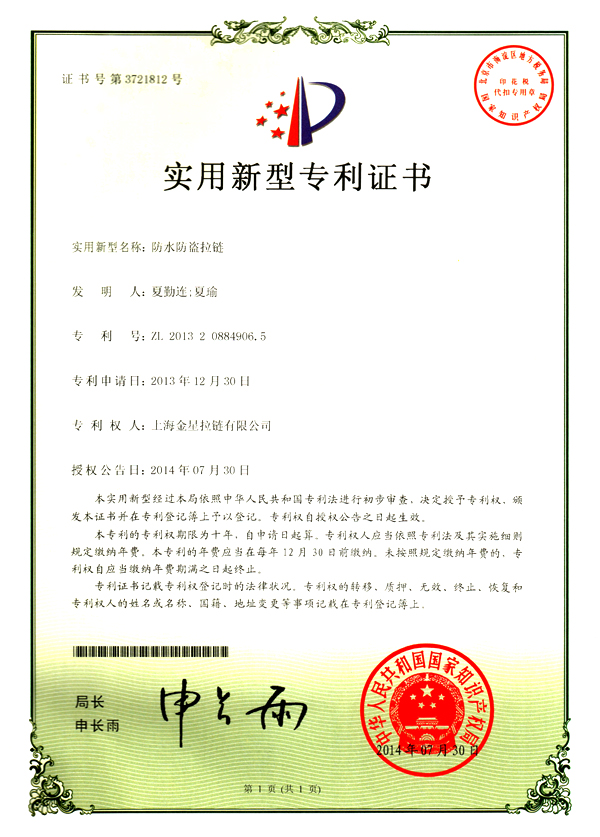

SGS acquired 6 national patent and production flow was re-arranged.

New anti-blasting /waterproof zipper production was set up, lateral strength achieved 1900 newton. Special appication level achieved.

2015

Hope for a better SGS.

2020.02.03

SGS is precious to provide material fighting COVID 19 with our expert knowledge of zipper production. SGS is destinated to fight with double boost.

2019.10

SHANGHAI GOLDEN STAR ZIPPER CO., LTD WAS LUKILY CERTIFIED WITH OEKO STEP LEVEL 3, SGS WILL KEEP ON MOVING FORWARD WITH SUSTAINABLE OPERATION.

2019.10

SGS zipper was first certified with OEKO-TEX STEP in China, with the support of STEP, SGS will continiously improve with ECO-FRIENDLY produciton.

2019.6

SGS ZIPPER IS CERTIFIED WITH BSCI AUDITING, WHICH MEANS SGS REPECTS COMMERCIAL ETHICS, OPERATS WITH SOCIAL AND ENVIORNMENTAL RESPONSIBLITYS.

2018.3

SGS zipper established a Industry-University-Research Collaboration with expert in material from Shanghai University, a perfect combination of experience and technology, makes a wonderful future of MADE IN CHINA.

2017.12

SGS is starting huge programe of achieving ZDHC requirement, contribute to a better world.

For more information pls refer to http://www.roadmaptozero.com

2016.11

SGS upgraded full-automatic production line, raised the hardware level, prepared for new seasons order from customer; at the same time, SGS started tactical management with 5"S" management, to avoid "seven waste", enforce the software level. With the support of "software and hardware", based on a "craftman"'s heart, SGS will have better products, more capacity and faster delivery.

2016.1

Under great pressure of slopping economy, SGS still won some of the order and built a strong basement of year 2016.

2015.4

Recently is production peak time, company is runningefficiently, a new project of "green energy" is going to start.

2014.9

New anti-broken zipper can be mass producted, new market is opened.

2014.6

5 invention pentent is approved.

2014.4

SGS is responding government, cleaning engergy project is prepared. SGS is going to use natural gas instead of traditional coal energy.

2014.2

Chinese new year, SGS new pentent project is finishing, 6-8 new invention pending approval.

2014.1

Production peak time, all products coducted with bar code, all order is running under tracable system.